autoLINE

As innovation leader on the market of commercial warewashing, HOBART GmbH went even one step further and brought a worldwide unique washing organisation on the market that allows trays, cutlery and crockery to be washed parallely in a single flight-type dishwasher:

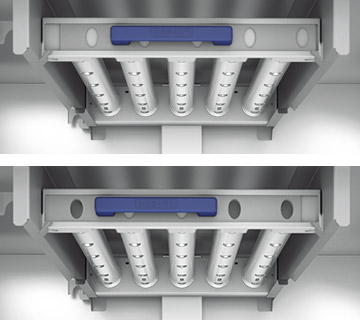

The patented and worldwide unique FLOW Line autoLINE dishwashing organising system makes it possible to wash trays and cutlery simultaneously with the other wash ware on a separate conveyor track, without increasing the footprint of the machine.

This innovative solution makes dishwashing faster while significantly increasing the machine capacity. For ease and comfort of operation, the trays are automatically fed in the entry section and stacked in the exit section of the machine.

A cutlery lifting magnet can be installed as an option ,as well, to save additional manual workload.

Optional: Feed stations perfectly integrated into kitchen layout optimise work processes and reduce staff workload!

Optional: One-person operation made easy. The compact, automated HOBART SMART LOAD wash ware feed system means the machine requires just one person to operate it without the overall installation requiring any extra space! The ergonomically positioned chutes of the HOBART SMART LOAD are individually adapted to the wash ware and are scalable in width, height and number of chutes.

The cutlery is automatically lifted from the tray at this point. The magnetic cutlery lifter is compact and easy to clean to provide maximum guaranteed hygiene.

The unit has no rotating parts that can wear and is therefore low-maintenance. Additional machine protection is provided by the automatic ejection of non-magnetic objects.

For automatic loading of cutlery onto the appropriate conveyor belt. Machine optionally available without separate cutlery track.

Upright tray loading saves space. High-pressure nozzles guarantee hygienic wash results. A turbo blower ensures optimum drying.

Lateral tray ejection with integrated tray stacker for continuous dispenser replacement during operation. Cutlery is dropped through a chute and into a basket in a contact-free process.

Your benefits at a glance:

EASY ACCESS

SPACE-SAVING AND COMPACT

FLOW Line autoLINE is designed to have the same width as a conventional conveyor dishwasher. This ensures easy all-round accessibility for cleaning and maintenance purposes.

Capacity: up to 25 trays/min

ASR² AUTOMATIC SOIL REMOVAL

Optimum wash water thanks to AI

High levels of soil in the entry section of the machine result in high water and chemical consumption. The AI-based feature ASR² identifies the degree of soiling of the wash ware in the machine and adjusts the pumping cycle accordingly.

SMART VISION CONTROL

Wash ware detection via artificial intelligence

Heavily soiled wash ware such as GN containers or pots require more intensive washing than plates or cups. By means of AI, the FLOW Line recognises the wash ware as soon as it is placed on the conveyor. If equipped with the respective performance package, it continuously adjusts the wash and rinse parameters such as conveyor speed, water volume

and wash pressure. SMART VISION CONTROL guarantees optimum wash results with minimum water consumption - regardless of who is operating the machine.

The FLOW Line autoLINE software has been trained with data of more than 80,000 pictures. The neuronal networks generated during this process identify the incoming wash ware within fractions of a second and immediately adjust the respective wash parameters accordingly.

HIGH LEVEL OF ECONOMY

THANKS TO EFFICIENT INNOVATIONS

Well-known HOBART features such as modern as the CLIMATE-PRO heat pump technology and the PREMAX inside features make the machine especially resource-efficient!

AUTO-CLEAN SELF-CLEANING SYSTEM

FAST, AUTOMATIC CLEANING

The optional system cleans the interior of the machine at the end of the wash cycle using special rotating cleaning nozzles.

Benefits: Saves time and money.

WASH ARM SLIDER

QUICKLY READY FOR CLEANING

Opening and closing the wash arms in a single action. No more separate capping. The optional AUTO-CLEAN feature also cleans the wash arms automatically.

More than 300 satisfied customers are proof of its success! Arrange a visit to an installation in your area.